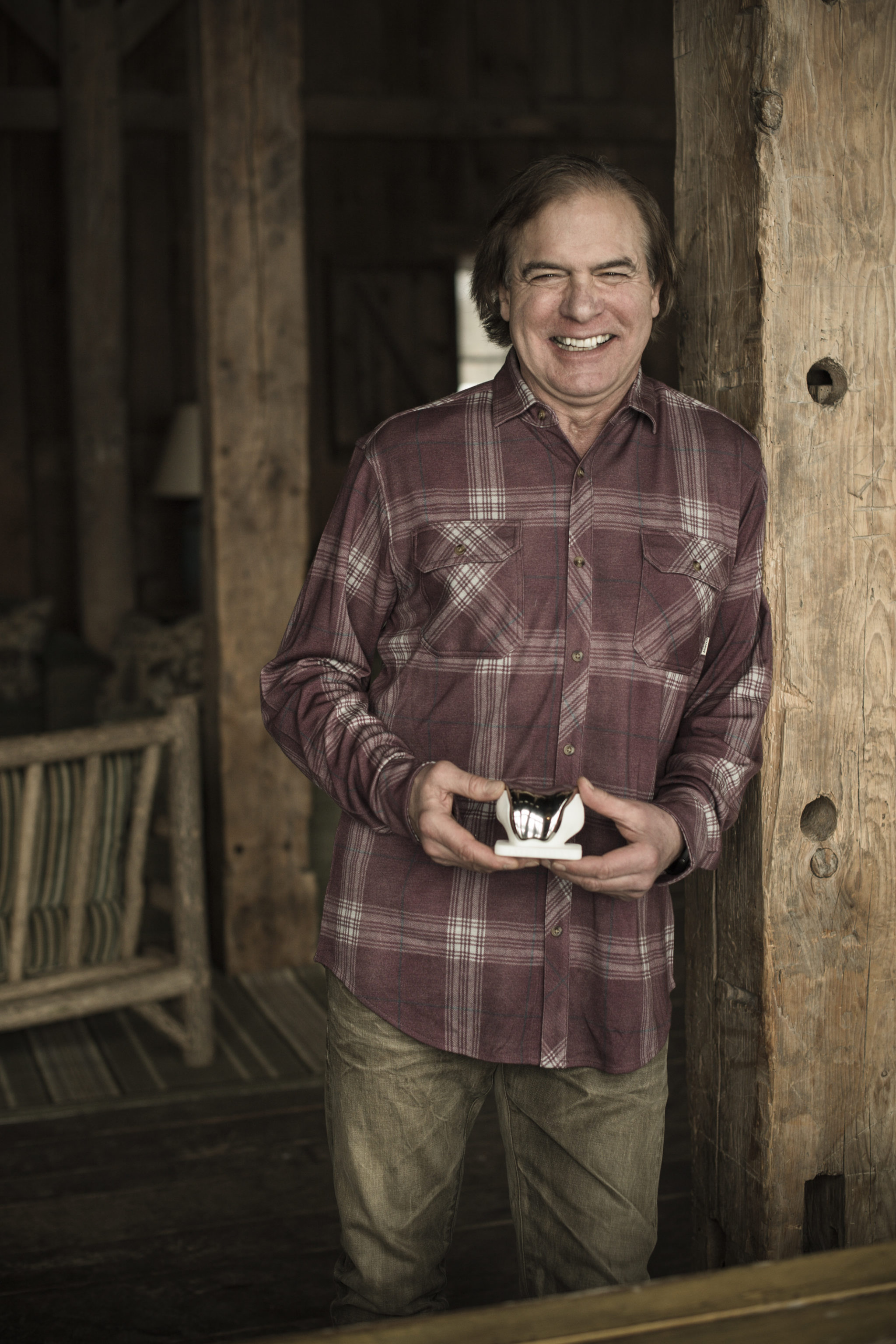

How the Founder of Burton Snowboards Got Back on His Board

The name Burton is synonymous with the sport of snowboarding. From tinkering with the very first snowboard designs in his garage in the 1970’s to building an industry-leading equipment and clothing company in Vermont that sponsors some of the best athletes in the world, Jake Burton Carpenter has been a driving force behind the sport from the very beginning.

So what did the founding father of snowboarding do when his knee pain got so bad he could no longer make it down the mountain? He turned to his good friend, Dr. Bryan Huber, and together with Conformis they made a plan to get him back on his board.

Jake’s Return to the Hill

Jake’s Conformis knee surgery with Dr. Huber went very smoothly, and within days he was up and walking independently. His biggest test came three weeks after surgery, when Burton hosted the U.S. Open Snowboarding Championships. Determined not to miss out on the fun, Jake strapped into his board and took off on a run with Dr. Huber following close behind.

“I felt like I could do what I wanted to do… I all of a sudden felt complete again.”

Jake went from being uncertain he would ever be able to snowboard again to cruising down the mountain in a matter of weeks. Since his Conformis surgery, he has regained the strength and range of motion he needs to pursue his passion for years to come.

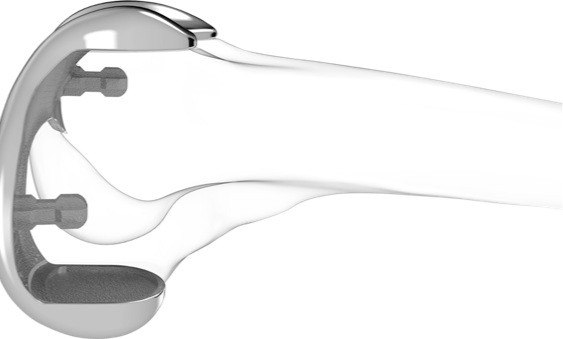

The Technology Behind the Knee

Conformis does something that we believe no other knee implant manufacturer has done. We put the patient at the center of implant design.

Unlike traditional implants, which are only available in a few sizes to fit an average range of patients, each Conformis knee is created specifically for each unique recipient. To accomplish this, Conformis uses an automated design process to model the size and shape of the knee joint in 3D. Proprietary software then takes this model and designs implants and iJig instruments to conform to the patient’s knee. A 3D printed wax mold is used to cast the metal components of the implant, and a set of disposable, patient-specific instrumentation is also 3D printed. These differences made Conformis an easy decision for Jake and his surgeon, Dr. Huber. After a CT scan of his knee, Jake’s custom-made implant was designed and built to meet his exact specifications.

Just a few weeks later, Jake was back up on his board.

Meet Dr. Huber

Dr. Huber is an attending orthopaedic surgeon at Copley Hospital in Morrisville, VT. In addition to being an avid snowboarder, Dr. Huber serves as the Medical Director for Burton Global Snowboard team and Team Physician for U.S. Snowboarding.

“ Each knee has a fingerprint. The curvature of each of the condyles, the center groove is all unique, and different. This technology allows each knee to individually be restored back to their native state.”

As both a personal friend and a highly respected surgeon, Dr. Huber was the natural choice for Jake Burton when he needed to address his knee pain.

Learn More about Conformis

If Jake’s story has inspired you to learn more about Conformis, consider getting in touch with one of our Patient Advocates to speak directly with someone who is living with a Conformis implant. You can also get in touch with our Patient Relations team to get help booking an appointment with a Conformis surgeon and to learn more about our technology and manufacturing process, or use the Surgeon Locator tool to find a Conformis doctor near you.

About Conformis

We start with a simple idea: make the implant fit the patient rather than force the patient to fit the implant

About Conformis